Research Facilities

Research Equipment

- Nano Fabrication Center

- Materials Characterization Lab

- Environmental Analysis Center

- Synchrotron Radiation Research Center

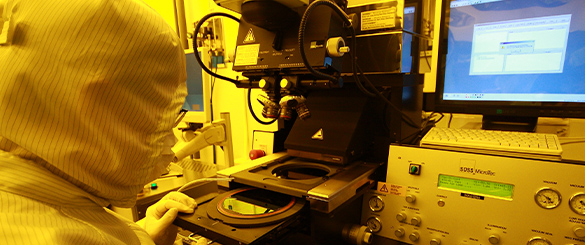

UNIST Nano Fabrication Center

- Clean room: Special closed space for manufacturing semiconductor/sensor device (maintenance of temperature and humidity, control of cleanliness)

- It possesses Class 100 & 1,000 (Class N refers to the number of particles of dust not exceeding N per square foot

Status of Facilities

| Contents | Details | ||

|---|---|---|---|

| Area / Class | 1,000㎡ / 100 | 992㎡ vertical layers with multi-layer structure Yellow zone 100 class and White zone 1,000 class |

|

| Composition of Equipment(units) | Photo | 9 | E-Beam lithography 1, Mask aligner 2, Nano imprint 1, Spin coater 3, 2 microscopes |

| Thinfilm | 14 | Furnace 2, ALD 2, Evaporator 2, LP CVD 1, PE CVD 2, Sputter 2 & etc | |

| Etch | 11 | Deep RIE 1, RIE 2, ICP 2, Asher 1, Wet Station 5 | |

| Inspection & etc | 10 | SEM, Ellipsometer, Profiler, Dicing saw, Bonder, etc | |

| Total | 44 | Capable of one-stop fabrication of multi-layer devices, etc. | |

| Number of processes / rate of operation | 15,000 cases / 46% | It supported more than 15,000 cases of process a year on the basic of unit process with the rate of operation of 46% for the clean room | |

| Area / Class | Establishment of new fabrication | Opening of new fabrication in jan. 2017 after two-fold expansion of its capacity, structure of vertical layers | |

Lithography process

Total process of forming MEMS/NEMS patterns and lift-off

Thin film deposition and etching process

Formation of the structure for deposition and dry etching of insulating nonmetallic thin film (oxide film, nitride film, dielectric thin film, etc.)

Measurement of characteristics of device

Experiment for measurement and analysis of contact / non-contact / electric characteristics / images by self-fabricated specimens

Wet cleaning process

Cleaning and wet etching of the surface of specimens using chemicals

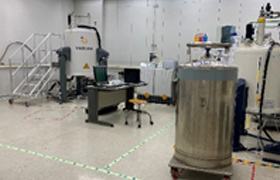

UNIST Materials Characterization Lab

- Equipped with the infrastucture for converged researches in which most advanced and expensive equipment are stacked, the center leads high-precision and high-resolution analysis techniques and supports development of new analysis techniques.

Materials Characterization Lab

| Contents | Details | ||

|---|---|---|---|

| Area (㎡) | 2,061 | ||

| Composition of Equipment (units) | Electron Microscopic Analysis Center | 31 | Advanced TEM, HR-TEM, CS-STEM, Normal-TEM, Bio-TEM, FE-TEM, FIB(3), SEM(5), Ultramicrotome(2), PECS, Electron microscope, equipment for pre-processing of specimens(14) |

| X-ray Analysis Center | 6 | HPXRD, NXRDX, HRXRD, HRPXRD, MPHPXRD, XRF | |

| Thermal and Property Analysis Center | 7 | TGA, DMA, DSC, SDT, Seebeck Coefficient analyser, Dilatometry | |

| Spectrometer Center | 9 | FT-NMR(2), Zeta Potential, FT-IR UV-Vis-NIR Microspectrometer, UV-Vis-NIR(2), AFM-Raman, Confocal Raman | |

| Mass Spectrometer Center | 8 | MALDI-TOF/TOF, GC/MS/MS, LC/MS/MS (ESI-MS), GPC-MALS, DART-HRMS, UPLC/MS/MS, EA(2) | |

| Surface Analysis Center | 7 | TOF-SIMS, XPS, XPS (UPS), AFM (2), BET (2) | |

| Number of analysis / rate of operation | Total number of analyses: 41,501 cases (Internal: 37,987 + Outside companies: 3,421 + Outside individuals: 93) / Average rate of operation of research equipment: 95.7% (As of 2020) | ||

TOF–SIMS, XPS, XPS/UPS, AFM

Analysis of composition, molecular structure and trace elements of surface 3D analysis through analysis of depth and distribution

TEM(5), SEM(4), FIB(2), Sample prep.

Observation of nano-scale micro structure and electronic imaging with high sensitivity at the atomic level Analysis of diffraction patterns Fabrication of nano device Observation of nano-scale patterning and image

MALDI-TOF/TOF, GC/MS/MS, LC/MS/MS, DART-MS, GPC-MALS, EA(2)

Verification of the molecular weight of macro-oragnic molecules, Analysis of impurities and byproducts, Qualitative / quantitative analysis compounds

NMR(2), FT-IR, Raman(2), UV-Vis-NIR(2), UV-Vis Microspectrometer, Fluorometer(3), Zeta sizer

Training of talents having creative knowledge and entrepreneurship Converged education for new materials / chemistry / physics / machinery / infrastructure, etc.joint research project by general / industrial-academic students

XRD(6), XRF

Analysis of crystal structure, chemical composition, and physical characteristics of materials or thin films, Analysis of thickness, roughness and density of ultra-thin films and analysis of orientation of substrates and thin films

Rheometer, thermoanalyzer (4), apparatus for measuring coefficient of thermal expansion, apparatus for measuring thermoelectric modules

Measurement of pyrolysis, thermal stability, oxidation stability, glass transition temperature, specific heat, melting point, degree of crystallization, etc.

UEAC : UNIST Environmental Analysis Center

- It supports work of national certified certification institutions (persistent organic pollutants measuring institutions and education and research work for top-class environmental analysis.)

Environmental Analysis Center

| Contents | Details | ||

|---|---|---|---|

| Area | 422 ㎡ | Environmental Analysis Center New Nonorganic Analysis Lab |

|

| Composition of Equipment | Organic analysis | 7 | GC/HRMS 3, LC/MS/MS, 2D GC/tof-MS, GC/MS, GC/ECD |

| Inorganic analysis | 4 | CP-TQ-MS, ICP-OES 2, LIBS | |

| Pretreatment | 34 | Rotary evaporator, Dry oven Heating mantle etc. | |

| Sampling device | 7 | Stack sampler 2, Gas analyzer 2, High volume air sampler 3 | |

| Total | 52 | Capable of analyzing micro-volume impurities | |

| Number of analysis / rate of operation | 1800 cases / 46.9% | It supported 1,800 cases of analysis with 46.9% rate of operation of equipment in 2020. | |

| Room class of the new Inorganic Analysis Lab | Under construction | Pre-processing room: 1000 class / Analysis Lab: 100 class | |

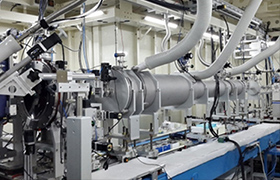

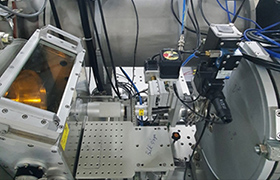

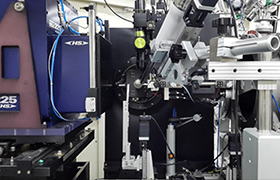

USRRL : UNIST Synchrotron Radiation Research Laboratory

- It supports diverse advanced researches leading basic sciences and development and researches of mext-generation energy materials, new drug materials, and next-generation display materials.

Conditions and Main Devices by Experiment Mode

| X-ray absorption sepecroscopy XAFS |

(Grazing) Small-angle X-ray scattering (GI) SAXS |

(Grazing) Small-angle X-ray diffraction (GI) WAXD |

X-ray single crystal Crystallography |

|

|---|---|---|---|---|

| Light source / spectroscope / resolution(ΔΕ/Ε) | Bending magnet / Si(111) dual crystal spectroscope / ~2×10⁻⁴ | |||

| Focusing mirror system | Toroidal, bendable (Coating materials: Rh 5 nm, Pt 35 nm) | |||

| Scope of Beam power(photen/s) / energy | 2×10¹¹ @10 keV / 520 keV | |||

| Beam size | (0.8 × 1.6) mm² | (0.6 × 0.8) mm² | (0.15 × 0.15) mm² | (0.12 × 0.12) mm² |

| Main experiment system |

|

|

|

|

Composition of beam line

Entrance of 6D UNIST–PAL Beamline

Entrance of 6D UNIST–PAL Beamline Data & EPICS PC

Data & EPICS PC HKL2000 PC & Optical Microscopy

HKL2000 PC & Optical Microscopy Experimental Hutch

Experimental HutchExperimental mode

(GI)-WAXD modes

(GI)-WAXD modes (GI)-SAXS modes

(GI)-SAXS modes X-ray crystallography mode

X-ray crystallography mode XAFS mode

XAFS mode

Smock Room

Smock Room Hallway

Hallway Wet Station

Wet Station Yellow room

Yellow room E-beam litho. room

E-beam litho. room White room#1

White room#1 White room#2

White room#2 White room#3

White room#3 Diffusion room

Diffusion room

Aberration Correcting Transmission Electron Microscope Lab

Aberration Correcting Transmission Electron Microscope Lab High Resolution Transmission Electron Microscope Lab

High Resolution Transmission Electron Microscope Lab Focused lon Beam Lab

Focused lon Beam Lab Scanning Electron Lab

Scanning Electron Lab Nuclear Magnetic Resonance Spectroscope Lab

Nuclear Magnetic Resonance Spectroscope Lab Secondary lon Mass Spectrometer Lab

Secondary lon Mass Spectrometer Lab X-ray Analysis Lab

X-ray Analysis Lab Integration Room 1

Integration Room 1 Integration Room 2

Integration Room 2 GC/HRMS Lab

GC/HRMS Lab Organic Analysis Lab

Organic Analysis Lab Inorganic Analysis Lab

Inorganic Analysis Lab Pre-processing Room

Pre-processing Room Pre-processing Room

Pre-processing Room Inorganic Analysis Lab (100 class)

Inorganic Analysis Lab (100 class) ICP-TQ-MS to be introduced(in 2021)

ICP-TQ-MS to be introduced(in 2021)